The SCDP is building on UNBC’s award-winning Energy Initiative and further demonstrating to the North the potential for sustainable energy. The project consists of a low-temperature, hot water district energy system to connect the student residences, campus daycare, and I.K. Barber Enhanced Forestry Lab to the Bioenergy Plant and the wood pellet system. The SDCP will expand UNBC’s renewable energy production, reduce greenhouse gas emissions and fuel purchase costs, and expand capacity for research, education, and demonstration. As such, it will serve as a model of energy security for Canada’s off-grid communities, many of which are located in British Columbia.

Completion of Infrastructure

In November workers finished installing the project's infrastructure, which included moving the 400 kW pellet boiler, a two-ton pellet silo, and laying the 650 metres of pipe from the Bioenergy Plant to the four buildings being connected to the SCDP.

Installation Underway - Fall 2014

October 22 was National Bioenergy Day, a timely opportunity to report on construction progress.

Watch the CKPG News Story - Oct. 22, 2014

September 2, 2014: The Project is Announced

Initial funders for the Sustainable Communities Demonstration Project. Back, from left: MLAs Shirley Bond and Amrik Virk, Michael Weedon of BC Bioenergy Network, and TransCanada Executive VP Alex Pourbaix. Front row: Mayor Stephanie Killam, UNBC President Daniel Weeks, and Brad Bennett of Pacific BioEnergy.

“When the Bioenergy Plant received a national Green Building Award earlier this year, the jurors commented that it’s ‘a fabulous example of what more communities in Canada should be doing.’ We agree, and the announcement of this Sustainable Communities Demonstration Project represents our next step. Thank you to our funding partners for joining with us on a project that will bring benefits to rural communities.”

- UNBC President Daniel Weeks

Pellet Plant Optimization

The primary heat supply for the SCDP is the 400 kW Pellet boiler currently heating the Enhanced Forestry Laboratory (EFL). Peak load and back-up heat will be provided first by the Bioenergy Plant, and second by the natural gas boilers in the Power Plant. While the Pellet Plant has been a highly successful research and demonstration site, the boiler is oversized for the heating requirements of the EFL alone. By increasing the demand on the Pellet Plant, the boiler will operate more efficiently, reducing maintenance and operating costs per unit of energy. At the optimal firing rate, the Pellet Plant will provide up to 90% of the heating to the Residences, EFL, and Daycare displacing roughly 8,500 GJ of natural gas and offsetting 425 tonnes of CO2e per year.

System Highlights

- Capital Cost: $2.2 Million

- Capacity: 400 kW Pellet Boiler (backed up by Bioenergy Plant)

- Buildings Heated: 4

- Fuel Input: 500 tonnes/year wood pellets

- Heat Output: 7,800 GJ/year

- Emissions Reductions: 425 tonnes CO2e/year

Fuel

The Pellet Plant consumes locally produced wood pellets donated by Pacific Bioenergy Corporation. The Pellet Plant will use over 500 tonnes of pellets per year to produce the hot water for the SCDP's low-temperature district heating system.

Laying the foundation for research and demonstration

Step 1: Piping Network Installation and Pellet Plant Relocation - Fall/Winter 2014

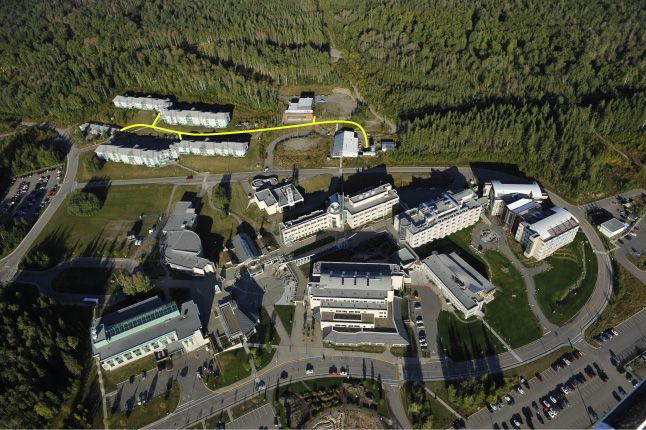

To distribute hot water to the Residences, EFL, and Daycare, a 650-meter pipeline is being installed. The Pellet Plant will be moved to a site beside the Bioenergy Plant where the pumping station will be located. The relocation of the Pellet Plant will allow for operational synergy between the two heating systems, and will simplify the fuel delivery. The pipeline will carry water at 80oC, as opposed to the 120oC of the district heating system heating the core campus.

Step 2: Equipment Replacement - Spring/Summer 2015

The four buildings being connected to the low-temperature district heating loop currently use natural gas to provide warm air and domestic hot water. In order to use hot water, the natural gas equipment will be replaced with new equipment that uses water-to-air and water-to-water heat exchangers.

Step 3: Future Expansion

The new pipeline is being installed with expansion and demonstration in mind, both in terms of accommodating future infrastructure on campus, and integrating and showcasing additional renewable heating technologies.

For example, the pipeline includes nodes where additional pipe can easily be added to accommodate an on-campus food production and additional housing.

Likewise, the lower temperature of the pipeline will allow alternative heating technologies – such as geothermal, solar thermal, and heat recovery – to supply heat to the loop. This will greatly expand UNBC’s ability to research and demonstrate sustainable energy in the North.

Funding Partners

- Government of B.C.

- TransCanada Corporation

- BC Bioenergy Network

- Omineca Beetle Action Coalition

- Pacific BioEnergy